Project overview and context

As a 3D printing enthusiast, I often struggled with quickly estimating how much a print would actually cost me (out of pure curiosity, friends often asked me the same question about the real cost of a print). Existing calculators felt either too complex or too limited.

At the same time, I wanted to experiment with no-code tools and explore the potential of AI-assisted research and vibe coding. This became the perfect opportunity to merge my personal interest with my professional curiosity.

Problem and idea

Most users and small businesses, face the same challenge: estimating print costs accurately. The main variables: filament, electricity, print time - are often calculated manually or by slicer software, but there’s no simple, user-friendly way to combine them into one clear cost breakdown.

The idea was to create a tool that delivers fast, simple, and reliable cost estimates, while being flexible enough to expand with more advanced features later.

An example of questionable quality and value of calculations available from the Bambu Lab app (slicer)

Research / data

To define the scope of the calculator, I conducted a desk research with AI (ChatGPT and Gemini). I explored:

what factors drive printing costs (filament, energy, printer power usage)

how existing online calculators work

where they fall short (lack of location-based energy prices, limited printer databases, confusing UX)

This gave me a clear picture: keep the tool simple, fast, and accurate enough for everyday use.

Preview of selected insights from my deep research (conducted in Gemini 2.5)

Solution (prompt engineering)

Before moving into prototyping, I prepared a short Product Requirements Document (PRD) to define the core scope of the MVP.

With the help of ChatGPT I transformed this PRD into a precise prompt that could be directly applied in Lovable, making the build process faster and more structured:

💬 Prompt for Lovable:

App Purpose:

The app allows users to calculate the total cost of 3D printing a model, factoring in printing time, energy consumption (based on printer model and country), filament cost, and model weight.

Features:

1. 3D Printer Selection:

Dropdown: choose from the top 3 most popular 3D printer brands (e.g., Bambu Lab, Prusa, Creality)

Second dropdown: select one of 5 most popular models from the chosen brand

Each model has a predefined average energy consumption value (used to calculate electricity cost)

2. Country Selection:

Dropdown with a list of countries (e.g., top 10–20 most relevant + country flag/icon)

Selecting a country automatically sets the average electricity price per kWh and the default currency

3. Printer Operating Time:

Dropdown to select hours (0–24 h)

Dropdown to select minutes (e.g., in 5-minute increments)

This input is used to calculate total energy usage

4. Filament Spool Cost:

Input field to enter the cost of a full spool of filament

Currency selector dropdown (default: the currency of the selected country, e.g., PLN, EUR, USD)

5. 3D Print Weight:

Input field for model weight in grams

The app calculates proportional filament cost based on spool cost and weight (assuming, e.g., 1000 g per spool)

6. “Calculate Cost” Button:

After clicking, the app displays:

Energy cost (printing time × printer power consumption × electricity price)

Filament cost (model weight × cost per gram)

Total cost = energy cost + filament cost

App Logic:

Power consumption values and electricity rates are predefined per printer model and country (easy to update later)

Currency is dynamically linked to selected country

All calculations are done locally – no API required

Example User Flow:

1. User selects "Bambu Lab" and model "A1"

2. Selects country: "Poland" (electricity cost: 0.623 PLN/kWh, currency: PLN)

3. Sets print time: 3 hours and 30 minutes

4. Enters filament spool cost: 90 PLN (default)

5. Enters print weight: 220 g

6. Clicks “Calculate Cost” → the app displays:

Energy cost: (0.15 kW × 3.5 h × 0.623 PLN) ≈ 0.33 PLN

Filament cost: (90 PLN / 1000 g × 220 g) = 19.80 PLN

Total cost: 20.13 PLN

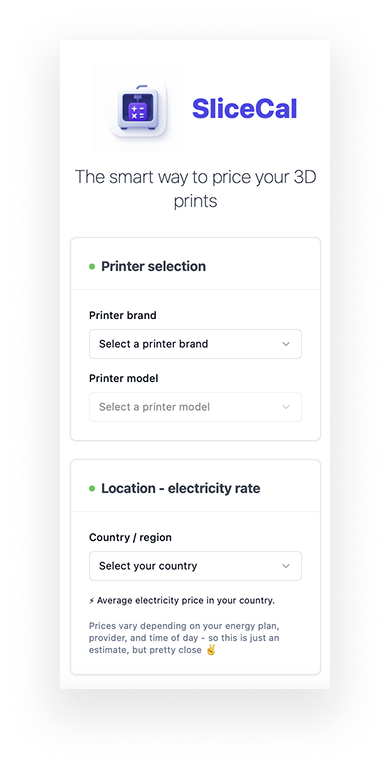

I then started designing and building a scalable web app in Lovable (no-code platform), which allows users to:

select their printer or input power usage

enter filament spool cost and consumption

adjust print time

calculate an estimated cost in seconds

The interface focuses on clarity and speed, avoiding clutter or unnecessary steps.

The first versions/iterations I get as a result of a precise prompt entered into Lovable

More versions for the app logo/icon (all made in ChatGPT)

Current desktop and mobile version (September 2025)

Process

✅ Conducted research on 3D printing costs and existing calculators, collecting detailed data on key cost factors (filament, electricity, printer power usage) and analyzing strengths and weaknesses of similar tools

✅ Defined core calculation logic with the help of AI

✅ Prepared a short PRD, which I transformed with ChatGPT into a precise prompt for Lovable

✅ Mapped out a minimal flow for cost estimation

✅ Prototyped the app in Lovable based on the generated prompt

Published online to test usability and gather user feedback (soon)

Outcome

A working app that quickly estimates 3D print costs

Easy to extend with new features (e.g., printer database, regional energy costs)

Already helpful for my own hobby projects and as a learning case for rapid prototyping

Future development ideas:

Add more printer models to the database

Include regional electricity cost presets for more accurate calculations

Expand material options (e.g., resin, advanced filaments)

Enable saving and comparing multiple print jobs

Explore integration with slicer software APIs for automatic data import

Testing the current version with users and feedback

In case of interest and increased traffic - ideas for monetization

Learnings

AI + no-code = rapid product and ideas validation

Simplicity is key: people want a “good enough” estimate fast, not a complex engineering calculator

Building for my own needs gave me stronger motivation and clearer priorities